To All HSA Business Associates

16th July 2020

To All HSA Business Associates

We have recently become aware that products competing with Helix™ Micro-Rebar are attempting to enter the Australian market.

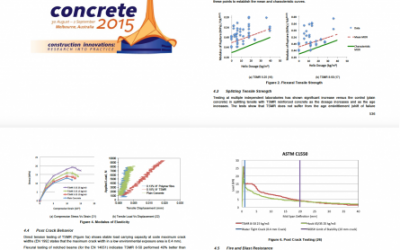

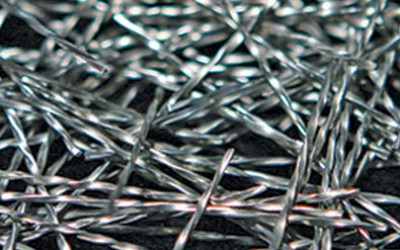

The Helix™ Micro-Rebar was originally developed for the US Military and has undergone a vast array of scientific, technical, quality control and field testing for more than 20 years.

The Helix™ Micro-Rebar has been used by our customers in virtually every type of commercial and domestic concrete project in Australia and around the world.

We are proud to say that our Helix™ Micro-Rebar is renowned for its dependability in the market and has an outstanding industry reputation with engineers, developers, builders, contractors, concrete supply companies, concreters and government agencies.

The Helix™

Micro-Rebar exceeds the requirements of Australian Standard 3600:2018, and is manufactured to our rigorous quality control specifications. This process is unique to the Helix™ Micro-Rebar and has consistently proven to result in products of the highest possible standard.

When considering the concrete reinforcement options for your projects, we strongly recommend that you undertake a thorough assessment of the suitability and adequacy of any competing products. For the best possible outcome, do not accept anything less than the time-tested excellence delivered by the Helix™ Micro-Rebar.

If you have any concerns or comments please feel free to contact us at any time at https://helixsteel.com.au/contact-us/.